Strategy behind the Standard

Good surface riding quality is essential for cyclist safety and comfort. This is the case whether cycling is on- or off-carriageway. Cyclists need a smooth riding surface, which should not be undulating and should have skid resistance appropriate to the location.

Best Practice Guidance to be used by Essex Highways

Cycle Infrastructure Design LTN 1/20 – Chapter 15.2.12 – Surfacing

London Cycling Design Standards 2016 – Chapter 7.2 – Surfacing

ECC Recommendations

Some recommendations for route surfacing:

- Surfaces should be sealed wherever possible. Despite sealed surfaces being more expensive to install, the additional cost is offset by reduced maintenance requirements following construction.

- Unbound surfaces should be avoided as they are generally unsuitable for utility cycling and in practice have proven to require regular maintenance and repair, being prone to erosion on gradients and easily damaged by horses.

- Surfaces should have a base binder course that is a 60mm layer of asphalt concrete with a coarse stone size overlain by a 20mm smooth asphalt riding surface. An 80mm single-layer (AC14) construction with 14mm stones is also commonly used.

- Surfaces should be machine laid to create a smooth riding surface.

- Surfaces should be well maintained and pot-holes, rutting and other defects are rectified immediately through patching, resurfacing or deeper trench reinstatements as necessary.

- Designers need to ensure that surfaces have adequate skid resistance value for cycling in both dry and wet conditions.

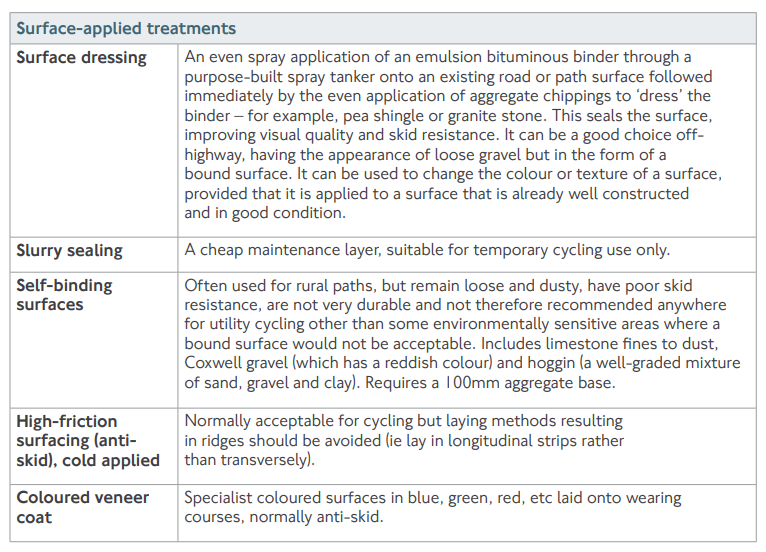

Visit our ‘Surface Materials’ page to see what materials are recommended for route surfacing. Please consider whether using ‘Recycled Surface Materials‘ as an alternative may be appropriate.

For information on coloured surfacing click here.

Sourced from: London Cycling Design Standards, Chapter 7.

How the Standard Should be Applied

Good riding surface quality should be provided and maintained on new and existing cycle routes that are both on- and off-carriageway. Surfaces should be applied in dry and warmer conditions (usually May to October).